BOY-YP06 Differential Pressure Transmitter

Product features:

1. High precision measurement: Provides high precision measurement over a wide measurement range to ensure data accuracy.

2. Easy operation and maintenance: equipped with a variety of display functions and built-in three-key quick operation to simplify the operation process; With comprehensive self-diagnosis function, easy to troubleshoot.

3. Wide applicability: Support liquid, gas, steam and other flow measured body, adapt to a variety of application scenarios.

▋ Product Description

BOY-YP06 is a high-precision, single-crystal silicon differential pressure transmitter designed for reliable and accurate pressure measurement across a wide range of applications, including liquid, gas, and steam measurement. It features intelligent static and temperature compensation to minimize measurement errors due to varying environmental conditions.

▋ Main Function

Description | |

Data acquisition | Collecting pressure information |

Data storage | Storing pressure data for future use |

Communication mode | 4-20mA output with HART protocol |

Communication protocol | Supports HART communication protocol |

Display | 5-digit backlit LCD display with multiple units (Pa, kPa, MPa, etc.) |

▋ Product Parameter

| ||||||||||||||||||||||||||||||||||||||||||||||||||||

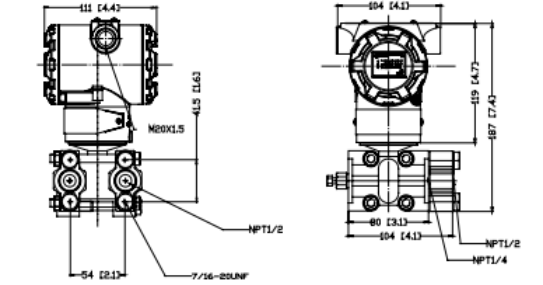

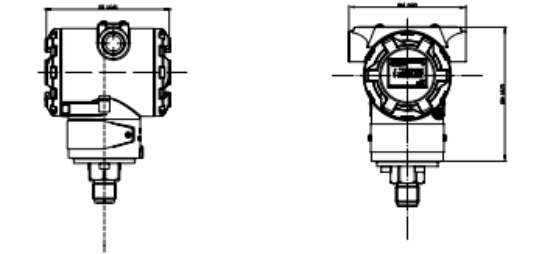

▋ Product Size

Differential pressure/splint type pressure transmitter

Pressure transmitter

▋ Measurement Method

The measurement method depends on the type of medium: when measuring liquid, the pressure inlet is set on the side of the pipeline, and the transmitter is installed near to facilitate the air bubble discharge; When measuring gas and steam, the pressure inlet is located at the top or side of the pipe, and the position of the transmitter is convenient for liquid backflow or condensate filling the pressure guide pipe, paying attention to avoid overtemperature. The liquid level measurement is realized through the differential pressure transmitter, considering the influence of the pressure inside and outside the container, the pressure guide pipe should be short and straight, the same temperature, no gas, and choose dry pressure guide or wet pressure guide connection according to the need to reduce the error

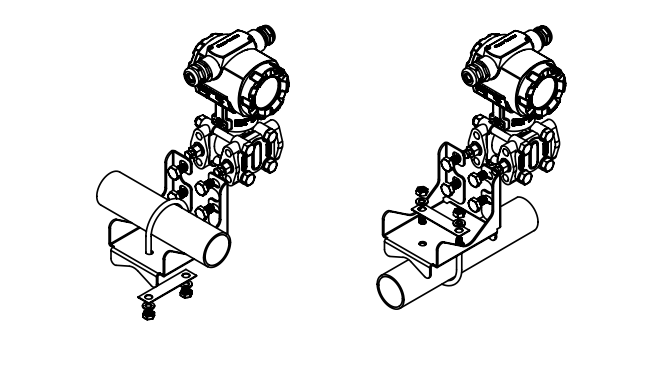

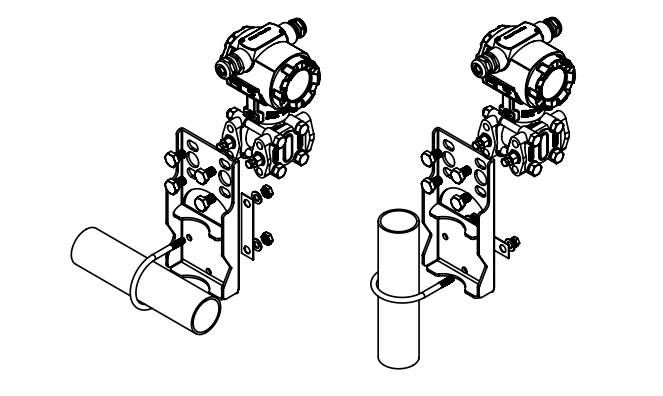

▋ Installation Method

When installing the BOY-YP06 differential pressure transmitter, be sure to comply with DIN 19210 and use a three - or five-valve set for commissioning and maintenance without interrupting the process. Outdoor installation should take anti-freezing measures, while avoiding the use of hard objects to contact the diaphragm seal to prevent damage. Ensure that the transmitter housing and the field display are adjusted to the best Angle as required for easy reading and accurate measurement.

▋ Application

The BOY-YP06 differential pressure transmitter is suitable for real-time pressure measurement in various scenarios, including lower interchange water, reservoirs, rivers, lakes, agricultural canals, and irrigation canals, offering solutions to complex urban construction challenges.

▋ FAQ

1.What is the electronic measuring principle? The BOY-YP06 uses the principle of direct contact measurement to determine the pressure data of the electrode.

2.What is the electronic pressure transmitter's measuring range? The transmitter covers a wide range of measurements from 0.1 kPa to 40 MPa, with specific ranges depending on the model.

3.Does the integrated electronic pressure transmitter need an external communication module? No, the transmitter is self-contained with built-in communication modules and can report data directly to servers or control systems.

4.How often does the integrated electronic pressure transmitter send data? The default setting is to collect data every 15 minutes and send it to the server every hour, but this interval can be adjusted as needed.

5.How long can the integrated electronic pressure transmitter supply power? Do you need an external power supply? The transmitter is designed for low-power operation and can be powered by an internal power source without the need for an external power supply, depending on the model and configuration.

Recommend

Online Service

Online Service