BOY-GC06 Ultrasonic static level

Product features:

1. High measurement accuracy, millimeter-level displacement and settlement monitoring can be realized

2. Industrial-grade design, high and low temperature resistance, suitable for harsh environments

3. Simple and convenient installation, easy to maintain

4. IP68 protection level, suitable for long-term stable operation in harsh environments

▋ Product Description

BOY-GC06 Ultrasonic static level is an intelligent sensing device designed specifically for monitoring the deformation of engineering structures. It uses high-precision ultrasonic sensors to directly measure the liquid level inside the container, and calculates the settlement by measuring the changes in liquid level between the reference point and the observation point. Real time measurement of millimeter level micro deformation, with IP68 protection level and explosion-proof certification, suitable for harsh environments such as -20 ℃ to 70 ℃, high humidity, strong corrosion, dust, etc. The entire system consists of multiple static level gauges and installation brackets, liquid pipes, gas pipes, collection boxes, etc. By seamlessly integrating 4G/LoRa wireless transmission with cloud platforms, we provide a long-term high-frequency vertical displacement monitoring solution between multiple points for scenarios such as geotechnical engineering, dams, bridges, tunnels, and mines.

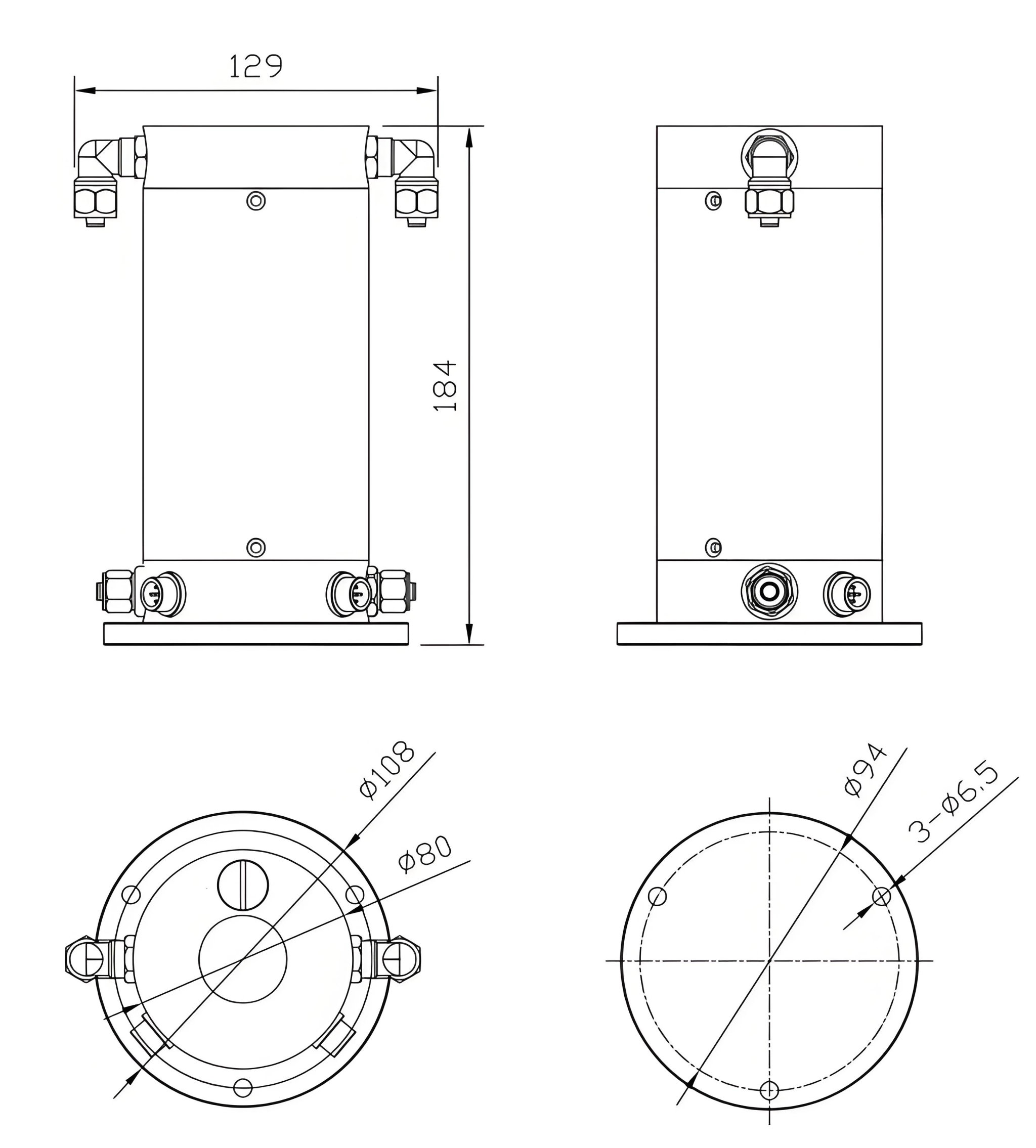

▋ Product Size

▋ Main Function

function | description |

Flexible monitoring | Horizontal/vertical multi-directional installation adaptation |

high-accuracy survey | Millimeter-level high-precision measurement (resolution 0.1mm) |

data transmission | Real-time data acquisition and remote transmission (support for 4G / LoRa) |

Data visualization | Cloud data visualization and automatic reporting |

temperature compensation | Automatic compensation of temperature drift and anti-interference algorithm |

data storage | Built-in large-capacity data memory card |

Multi-protocol compatibility | Supports a variety of industrial protocols (Modbus, RS485) |

Low power consumption | Support for low-power sleep working mode |

▋ Product Characteristics

BOY-GC06 The cup body of the ultrasonic static level gauge is made of acrylic material. The liquid level is visible, which is convenient for liquid filling. It has lightweight and impact resistance, and can work stably in rainstorm, water seepage, oil and gas environment for a long time; Waterproof five core shielded cable, with anti-interference, anti-corrosion and other characteristics, greatly reduces the data environment error of the entire system; Adopting independently innovated high-precision ultrasonic sensors with an accuracy of up to 0.1mm; Built in tilt angle sensor, which can better determine the status of the installed equipment; No float design, long-term stable data; At the same time, it is equipped with a circular level to facilitate equipment installation and leveling, and to determine the horizontal status of the equipment. Modular design supports rapid deployment and expansion, significantly reducing monitoring and operation costs in scenarios such as subways, reservoirs, and slopes.

|

|

|

Remote data telemetry | High stability | visual display |

The 4G / GPRS communication function can realize long-distance communication in the field without manual observation | No float design, data long-term stability | Transparent acrylic tank body with liquid level visible |

|

|

|

building block design | IP68 protection grade | high-accuracy |

The equipment height is below 20 sides, and the installation is not limited by the environment | Corrosion resistance and strong environmental adaptability | And 0.1 mm measurement accuracy |

▋ Product Parameter

plant parameter | |

Measurement medium | anti-freeze fluid |

measuring range | 50mm / 100mm (default) / 200mm, customizable |

certainty of measurement | 0.1mm |

Minimum acquisition time | 1s |

Power start time | 10s |

Work power consumption | 0.6W |

Electrical connection | Waterproof five-core aviation joint |

output signal | Digital signal, RS485 |

protocol | modbus protocol |

Baud rate | Supporting the Porter rate range from 2400 to 115200 |

working voltage | DC9-36V |

insulation resistance | ≥100MΩ |

working temperature | -20℃~60℃ |

Working humidity | 5%-95% |

temperature compensation | -20℃~70℃ |

Main material | Aluminum alloy base, acrylic cup body |

levels of protection | IP68 |

way to install | L-type support for auxiliary mounting |

▋ Application

BOY-GC06 The ultrasonic static level system is used for monitoring vertical displacement of large storage tanks, dams, high-rise buildings, foundation pits, tunnels, bridges, subways, and other structures. It can provide real-time warning and processing for settlement and tilt conditions, and provide settlement data and monitoring services for the monitoring center.

▋ Working principle

BOY-GC06 The ultrasonic static level utilizes the principle of a connector, where multiple connecting pipes are connected together in a liquid tank, and the liquid level is always on the same level. When a settlement occurs at a certain point, the liquid level height of each device at that point will change. The relative settlement and differential settlement of each static level can be calculated by the change in liquid level height at each monitoring point. The height of its liquid is measured by an ultrasonic sensor, and the height of the liquid level is obtained based on the time difference and sound velocity between the emitted and reflected ultrasonic waves and the excitation.

Q1: Is ultrasonic measurement affected by temperature?

Built in temperature compensation module, automatically corrects sound velocity errors within the range of -20 ℃~70 ℃.

Q2: Does the waterproof rating support underwater installation?

IP68 protection can withstand immersion in water up to 1.5 meters deep, but a customized sealing solution is required for long-term underwater use.

Q3: Can it be integrated with third-party platforms?

Supports Modbus/HTTP/MQTT protocol and is compatible with over 90% of industrial software.

Q4: How long is the battery life?

Default 5 years (1 sampling per minute), supporting solar power expansion.

Q5: Does extreme dust environment affect accuracy?

Ultrasonic frequency can penetrate dust, and the algorithm automatically filters out particle interference.

Q6: How long is the warranty period?

The whole machine comes with a one-year warranty and lifetime technical support.

Recommend

Online Service

Online Service